Everything You Need to Know About Knife Handles

Dec 25th 2018

Knife handles are an essential consideration in your knife purchase. Selecting the right handle is more than a matter of aesthetics. For all but the most casual use, choosing a knife with the right handle must be a well-informed decision. A knife handle should be comfortable to hold, easy to grip, and sturdy enough for tough jobs.

To get the most long-term, effective use from your knife, compare how you plan to use it—as a tactical, hunting, survival, or collector’s item—with the pros and cons of each handle type.

Handle Composition Options

Knife handle materials are metal, synthetic, or natural. Natural materials like bone and wood are classic choices, but they are not as popular or practical. Newer technologies for synthetic and metal options like carbon-fiber and titanium knife handles offer greater durability for some uses.

In addition to carbon fiber handles,Micarta, G10 (a Garolite laminate composite made of fiberglass), and Zytel (Fiberglass Reinforced Nylon or FRN) provide excellent grip and are rustproof and waterproof. Both strong and lightweight, their manufacture also includes interesting and useful handle design elements like textured grips.

The G10 has similar properties to carbon fiber and costs much less. It is excellent for tactical-use folding knives and for fixed blades. FRN is the most economical handle due to its injection molding process, and the nonlinear arrangement of its nylon fibers makes it the strongest synthetic handle.

Metal knife handles include stainless steel, aluminum, and titanium, each with its own benefits. The advantage of aluminum’s light weight is offset by its more limited resistance to impact. Stainless steel is more impact-resistant and an inexpensive choice, but heavier. It also requires more care and maintenance.

Titanium is extremely lightweight and resistant to corrosion, but quite expensive. All metal handles are tough and durable, requiring minimal maintenance. Since a metal handle is slippery, additional design elements may be included on the handle to overcome this fact.

OTF Knives

OTF knives, because of their unique mechanical features, need a sturdy handle to keep the mechanism and blade steady. Most OTF knives are crafted using G10, anodized alloy, aluminum, stainless steel, and titanium.

The handles on these knives usually feature a gripping surface for better holding, slicing, and cutting with precision and accuracy.

OTF (out-the-front) knives typically have metal handles. Also known as telescoping, sliding, and switchblade knives, OTF knives are typically stainless steel or synthetic. They use an internal mechanism, allowing the knife to deploy and retract via thumb slider or button. They are the first choice of military, law enforcement officials, and first responders. The single-action blade is also an OTF option, but less effective in emergencies.

Folding Knives

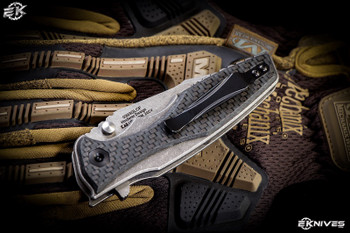

Folding knives generally have more flexibility in their handle choices. As most folding knives are used as pocket knives, their versatility ranges from tactical and survival tasks to opening boxes and cutting twine.

Folding knives come with handles as heavy and durable as stainless steel or titanium, or as lightweight as aluminum. G10, Micarta inlays, and wooden inlays are also popular options for folding knives. In general, wooden handles require more maintenance and upkeep, but wooden inlays are simple to clean.

Fixed Blade Knives

Fixed blade knives require a heavy handle, as these knives are typically used in survival, knife-throwing competitions, and hunting. While they don't have hinges that can break, the handle needs to support a blade that is up to twice as long as other knife styles.

G10, fat carbon, and Micarta are common synthetic handle choices for fixed blade knives. Many of these knives are also made with polymer handles, which is similar to the polymer used in the frames of popular handguns such as the Glock 17, the SIG Sauer P320, and the Smith & Wesson Bodyguard. The polymer stands up to extreme temperatures and hard hits.

Tactical Knives

Tactical knives are for military or other hard/quick use, and their design reflects that. The type of material varies for tactical knife handles, though synthetic handles offer great benefits with their layers for maximum durability. Micarta, G-10, or carbon fiber are all synthetic handle options. Their design aesthetic tends to reflect their use, with a camouflage, “snakeskin,” or other heavily textured handle polymers.

A survival knife may need to be used for cutting, slicing, digging, splitting wood, light-duty hammering, making tools, building shelters, first aid, food prep, or self-defense. It should be a fixed blade knife, not a folder, with a full-tang blade that goes through the entire knife handle for maximum durability that supports its often-heavy-duty uses.

Final Word

Whatever your planned knife use, try out many handle options before you buy. Balance their grip, heft, durability, aesthetics, and planned use in making your final decision. At eKnives, we have a huge selection of blades with specialized handles to fit your needs. Explore our inventory or contact us at (423)-525-9477 for assistance.