How to Sharpen a Custom Knife

Posted by Clayton on Jul 16th 2015

A frequent sharpening mistake beginners make is using too much pressure on the knife while sharpening. Using a light grip and comfortable pressure on the knife works best. Allow the stone do the job and maintain a steady angle and continuous pressure on the stone.

Maintaining a constant angle is more important than the product you are using to sharpen the particular angle. A 20-degree angle to the surface of the blade is ideal.

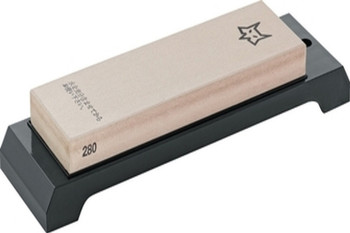

A long standing method of sharpening blades is with the use of stones. Use a rough stone with low grit density for the initial pass, then use medium stone, a fine, and ultra-fine. The duller the blade, the longer the time it takes to get a good edge.

Most sharpening stones work wet or dry, but others break down quickly when oil is used. It is important to understand the manufacturer’s guidelines on stones. If oil is used on the wrong stone type, it causes the collapsed cutting fragments to obstruct the stone’s surface. The oil can also over-lubricate the surface and slow the sharpening process.

Verify the sharpness of the blade by using it to cut a piece of paper. If the knife cuts neatly through it without tearing or bending the page, then the blade is adequately sharp.

Sharpening Knives with Bench Stones

You can maintain the sharpness of your knives with a high-quality sharpening stone. No matter the type of knives you own, a sharpening stone is necessary for preventing your blades from becoming dull.Choose the appropriate coarseness for your bench stone.

An important initial step in sharpening your knife is determining the proper coarseness for your bench stone. All knives do not require sharpening with the coarsest stone. Consequently, you cannot sharpen a dull knife using only your finest stone. Starting with the appropriate coarseness ensures you will quickly attain the edge you need.

Begin with the coarsest stone if your knife is very dull or has a chipped blade. A coarse stone removes substances quickly, so a dull edge is honed speedily, and then use your finer stone to refine the edge. If the blade is only somewhat dull and needs a quick touch-up, then beginning with a medium or fine stone will save time. Starting with a fine stone involves fewer steps, but this is only used for an edge requiring little work.

Choose the proper bevel angle.

Picking the appropriate sharpening angle is the next step. Select a bevel angle regardless of the sharpening method. The angle does not need to be precise, but it is a good idea to follow some general guidelines.

Most knife manufacturers recommend about a 20-degree angle. Contingent upon the use of your knife, you can increase or decrease that angle. For instance, a fillet knife is never used on a hard surface, so an angle a few degrees less will create a sharper edge.

Consequently, a survival knife with varying purposes is more useful with a sturdier edge a few degrees higher.

Add water or oil to the stone.

Some stones require water and some need oil for floating away the small metal filings produced while sharpening. Add a few drops of the proper liquid directly on the stone. The type of stone you are using determines which liquid you need.

Now sharpen your knife.

Begin with the coarsest stone required for your knife, and then proceed using each finer stone until you have the necessary level of sharpness.

Place the knife on the stone at the appropriate bevel angle. A natural means for choosing the angle by sight is to imagine a 45-degree angle and then use half that amount. That provides an estimate of the angle you need, and then you can adjust appropriately higher or lower.

Using a slicing motion, bring the length of the knife across the stone, starting with the heel of the knife and ending with the point of the knife. This movement should look like a sweeping arc pattern across the stone. Be sure to keep the angle of the knife on the stone.

Knives that are longer and curved add extra challenges, but, as long as you maintain the angle, your knives will be sharpened efficiently. Replicate this process on the opposite side of the knife, and continue to repeat until your knife is sharpened through all stone grits.

Know when to move on to the next stone.

Knowing when you are finished with one stone and ready to go on to next finer grit is essential, but sometimes it is unclear. It is simple with coarse stones, since after sharpening one side you will notice a burr developing on the opposite edge’s side. Very carefully feel for the burr by running your hand gently from the back to the edge. A burr develops when the stone eliminates debris directly at the edge.

As you alternate sharpening sides, the burr moves from one side of your knife to the other. Be sure you have felt the burr move between each side before going on to the next finer stone. This ensures both sides are sharpened successfully.

The finer grits are performed in the same way, except the burr is now much smaller, so you may be unable to detect the burr at all. Testing the sharpness of the knife will clarify when you are finished.

Determine the level of sharpness.

The sharpness of the edge is established by the bevel and how fine a grit you select for the final honing. Since you have already decided on your bevel angle, you now just need to determine at which grit you can finish, which depends on the knife’s use. Typically, you can go completely to the finest stone that you have since this will provide you with the best edge.

Choosing Your Sharpening Stone

Oil stones

These traditional stones are created from one of three materials, either novaculite, aluminum oxide, or silicon carbide, and all need oil to remove metal filings.

The most conventional oil stones are made from novaculite. These stones are mined in Arkansas and processed to create Arkansas stones. They are divided into several grades according to the density and texture a stone creates on a blade. The most coarse grade is referred to as Washita, and it is very soft.

Finer grades are referred to as “Soft Arkansas,” “Hard Arkansas,” “Hard Black Arkansas” and “Hard Translucent Arkansas.” These unprocessed oil stones can create a refined edge, but are inclined to cut more slowly than synthetic stones.

Aluminum oxide oil stones are an especially well-liked synthetic choice. The most popular is the India Stone. They cut quickly, create a fine edge on knives, and are graded fine, medium, or coarse. India stones are more coarse when compared to Arkansas stones.

The quickest cutting oil stones are made from silicon carbide;are referred to as Crystolon stones; and are categorized as fine, medium, and coarse. Even though these stones will not create as fine an edge as the India or natural stones, their quick cutting ability makes them perfect for initial coarse sharpening.

The best advantages of the oil stone are the overall effectiveness and the cost. A disadvantage is they are difficult to clean.

Water stones

Water stones are relatively new but have amassed a large following because they have numerous advantages. They are available in natural and synthetic materials.

Synthetic water stones are made from aluminum oxide, which is the same coarse material used in India stones, but the difference is in the binding agent that keeps the abrasives in the water stone collected. Since water stones are softer than India stones, they encourage faster cutting, as the old coarse substances break away and are swapped with new sharp substances.

Quick cutting is certainly an advantage of using the water stone. The other most notable advantage is the use of water instead of oil to remove the debris from the stone. The water stone is soft and wears down faster.

Diamond stones

These stones consist of small diamonds attached to the surface of a metal plate. They are small, industrial diamonds which are harder than any other sharpening stone.

Two main types of diamond stone styles exist. The most common style has holes in the diamond surface to catch the debris. These stones are cut at a very quick speed and are easy to use.

The second type is the continuous diamond surface, which is favorable when sharpening tools with points that get trapped in the niches of the non-continuous diamond surface. These diamond stones are available in monocrystalline and polycrystalline diamonds. The monocrystalline diamonds last longer.

The principal advantages of the diamond stone are the very quick sharpening ability and the flatness maintained by the diamond stone. The downside is their cost.

Errors That Can Dull Your Knives

Taking appropriate care of your knives will help them remain sharper for a longer period of time. However, simple errors can lead to fast-dulling knives. Here are some common mistakes and how to avoid them.Storing your knives in a drawer.

Knives stored in drawers become dull quickly. This is mainly due to the fact the blades bump against other blades or objects when the drawer is opened, which causes nicks in the knife blades. This is especially true if you happen to store your knife in a kitchen drawer

To store knives correctly, use one of these preferred methods: either a knife block, with the slits horizontal and not vertical, or a magnetic storage strip. This keeps your knives secure and prevents them from becoming scratched or bent from hitting one another. Store tactical knives in a sheath to protect them from damage.

Placing knives in the dishwasher.

A lot of people wash their best knives in their dishwasher, which is a bad idea for several reasons. First, the knives get knocked against one another and other silverware, causing nicks and bending of the blades. Second, the chemicals in most dishwasher detergents can react with the handles and steel of the knives, and create corrosion and discoloration of the knives.

Clean your kitchen and tactical knives promptly by hand in your sink, without using strong chemicals. Dry them and store them immediately after washing. This process ensures that your knives remain sharp between uses and will not become discolored.

Overlooking the sharpening steel.

Many knife owners are uneasy with using the honing steel, and do not use it, since they are unsure of how to. It should not represent a threat, as the honing steel does not sharpen the knives, but merely straightens the blades and removes nicks and dents.

Using glass cutting boards.

Many beautifulglass cutting boards exist, and consumers are likely to purchase these for their appearance. However, cutting on these boards quickly dulls knives, since the glass is harder than the knife blade, which causes the blades to bend and flatten.

To prevent the knives from becoming dull on the cutting board, you should use a bamboo cutting board.